Publication

868

J. Am. Chem. Soc. 140 (51), 117830–178345, 2018

DOI:10.1021/jacs.8b09740

|

|

|

|

|

|

|

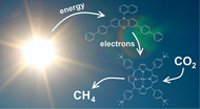

Visible-Light-Driven Conversion of CO2 to CH4 with an Organic Sensitizer and an Iron Porphyrin Catalyst

|

|

|

|

Heng Rao, Chern-Hooi Lim, Julien Bonin, Garret M. Miyake, and Marc Robert

Université Paris Diderot, Sorbonne Paris Cité, Laboratoire d’Electrochimie Moléculaire, UMR 7591 CNRS, 15 rue Jean-Antoine de Baïf, F-75205 Paris Cedex 13, France

Department of Chemistry, Colorado State University, Fort Collins, Colorado 80523, United States

Using a phenoxazine-based organic photosensitizer and an iron porphyrin molecular catalyst, we demonstrated photochemical reduction of CO2 to CO and CH4 with turnover numbers (TONs) of 149 and 29, respectively, under visible-light irradiation (lamda > 435 nm) with a tertiary amine as sacrificial electron donor. This work is the first example of a molecular system using an earth-abundant metal catalyst and an organic dye to effect complete 8e–/8H+ reduction of CO2 to CH4, as opposed to typical 2e–/2H+ products of CO or formic acid. The catalytic system continuously produced methane even after prolonged irradiation up to 4 days. Using CO as the feedstock, the same reactive system was able to produce CH4 with 85% selectivity, 80 TON and a quantum yield of 0.47%. The redox properties of the organic photosensitizer and acidity of the proton source were shown to play a key role in driving the 8e–/8H+ processes. |